Biogas

What is Biogas?

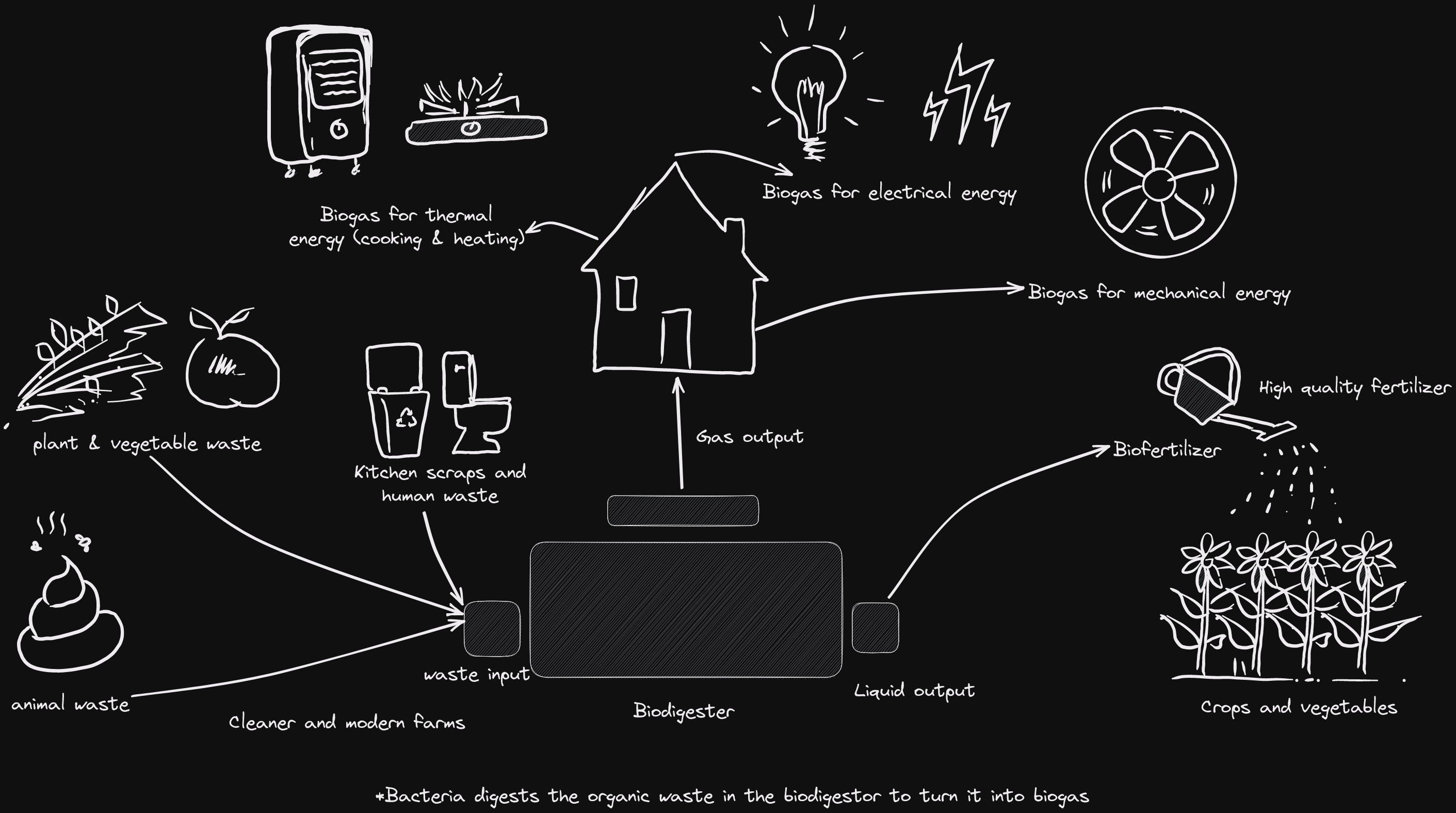

Biogas is a renewable energy source. It is produced from natural sources like wetland, marsh land, moors – animals like ruminants (e.g. beef and dairy cattle) and organic waste like food waste, agricultural waste, manure, sewage and biowaste in landfills. Biogas comprises of several gases – methane, carbon dioxide, moisture and small amounts of hydrogen sulfide and others.

Biogas is generated by microbial decomposition of organic matter in a wet or moist environment excluding air – anaerobic digestion. More than 3 billion years ago – when life on earth began – anaerobic microorganisms developed.

Biogas can be purified to bio-methane 50-75 % and carbon dioxide 25-50 % with some traces of other gases – similar to natural gas. Purified biogas can be compressed like natural gas to CNG and used as fuel for cars, heating systems and industrial applications.

The digestate can be used as an effective fertilizer. Compared to manure being used directly in the fields the green house effect as well as the release of ammonia is considerably reduced. Studies with mixtures of fertilizer and digestate show that for most crops more than 50 % of fossil fertilizer can be substituted by digestate obtaining a similar yield.

Special care is needed concerning the storage of digestate in large quantities because methane production does not stop. Because of the high global warming potential of methane (25x higher than carbon dioxide, UBA 18.11.2022) a gas tight sealing of the plant and the storage tanks for digestate are compulsory.

What is the Impact of Biogas Plants on Energy Supply ?

Large biogas plants are operating CHP (Coupled Heat and Power) units. In Germany more than 9000 biogas plants provide 4800 MW / 31,7 billion kWh – 5,5 % of the total consumption of electrical energy (IEA + UBA 2021) – . 18 billion kWh of heat have been used locally for heating buildings e.g. district heating networks. Not accounted is the share of the heat being used to optimize and stabilize process temperature and output of bio-methane.

Because of its availability independent of the weather Biogas can be used like fossil energy resources – which makes biogas a reliable technology – being able to balance the weather dependence of wind and solar energy.

Benefits

Renewable and sustainable energy source

Biogas is produced from organic waste like food waste, agricultural waste, manure, sewage and biowaste in landfills. Therefore biogas is a renewable energy source. It is sustainable because it releases only carbon dioxide which has been captured before by photosynthesis of the plants used as input substrate. An eco-balance of e.g. electrical energy produced by a biogas plant compared to a fossil power station confirm that the total carbon dioxide emissions are less than 50 % (Biogas Wissen)

Decreases reliance on fossil fuels

Biogas can be used as a substitute for fossil-based natural gas, which helps to reduce our reliance on finite fossil fuel resources.

Reduces greenhouse gas emissions

Biogas is a clean energy source that produces fewer greenhouse gas emissions than fossil fuels. But methane emissions have a 25 times higher global warming potential (GWP) than carbon dioxide. Therefore biogas being produced from wet biowaste in landfills by anaerobic digestion needs to be captured and used as energy source. This helps to combat climate change.

Some organized landfills in South Africa use already these biogas quantities. But comparing the potential of biogas production in a biogas plant the efficiency is lower.

Using the digestate as fertilizer in gardening/horticulture and agriculture helps to significantly reduce the use of fossil fertilizers. Therefore also green house gases for production and handling of fossil fertilizers are served.

Provides a useful way to dispose of organic waste

Biogas being produced from organic waste is a renewable, sustainable energy source. When burning biogas only carbon dioxide is produced that has been captured before by the plants by photosynthesis.

Biogas plants turn organic waste which cannot be used as feed for man or animals into a clean and sustainable energy source and a fertilizer for horticulture and agriculture.

Local energy production

Biogas can be produced locally, which means it can reduce the need for long-distance energy transmission and improve energy security.

Creates economic opportunities

The production and use of biogas can create economic opportunities in the form of jobs and business opportunities in the renewable energy sector.

Improves Social Development of Communities

The social environment of the biogas plant is important. The demand for input material and preparation of it for the biogas plant as well as the distribution of the digestate as fertilizer for gardening/horticulture creates jobs and the opportunity for good communication of the group of people involved e.g. on a farm, a restaurant, a small district with houses or condominium where the biogas plant belongs to.